Asset Reliability Inspections Pty Ltd (ARI) is an asset integrity/compliance company that offers pressure equipment inspection, pressure equipment design verification, weld inspection and non-destructive testing (NDT) services.

Our inspectors are available 24 hours a day, 7 days a week to meet your inspection needs and conduct themselves in a professional manner, with both safety and your plant reliability in mind.

ARI have Heavy Machinery Inspectors that can find cracking before it becomes critical using visual, eddy current and ultrasonic testing techniques.

Our AICIP, API and ASME certified inspectors meet this definition and are competent in pressure equipment inspections.

ARI offer the full range of NDT services including magnetic particle testing, dye penetrant testing, radiography, ultrasonic testing of welds, ultrasonic thickness testing and more specialised testing services.

ARI has researched and developed proprietary ultrasonic testing techniques, using custom made equipment to test from the bottom of the stud, eliminating the requirement to remove the grease caps, saving 45mins downtime per truck.

ARI have teamed up with Total Heat Treatment Services to provide the high level heat treatment services that our clients require.

ARI are able to work in a broad range of tank industries including petroleum, chemical, water and more.

We utilise the latest Residual Field Magnetic Flux Leakage Technique. Residual Field MFL works through the inspection and analysis of the residual magnetic field of a magnetised ferromagnetic wire rope.

ARI have competent, AINDT certified technicians who are highly experienced in eddy current inspections of in-service equipment including cranes, excavators, shovels and bridges.

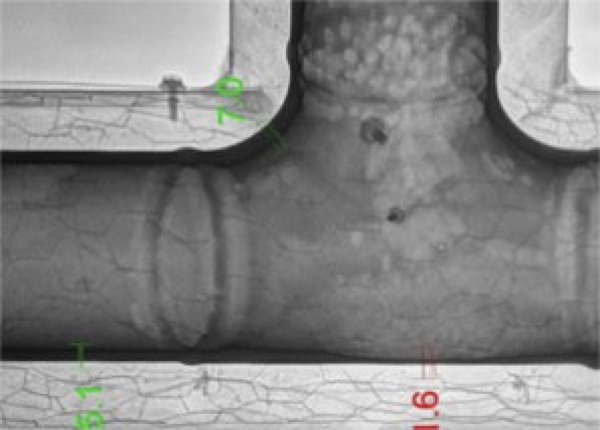

Digital radiography has been in use in Australia since 2005 and recently is gaining significantly more acceptance/use. ARI was one of the first companies to take up this technology and have ISO9712 certified staff specific to this technology.

ARI have certified Weld Inspectors that can witness, record variables and create weld procedure specifications (WPS) to both Australian and International Standards.

The ARI Delta Professional handheld XRF is one the best PMI analysers on the market with light element detection capability supported by our extensive sample material library.

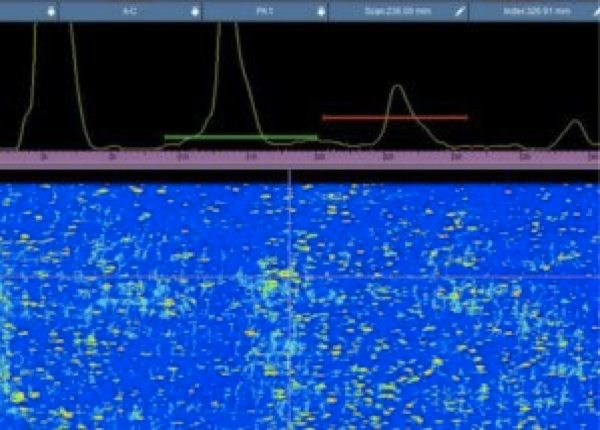

ARI are leaders when it comes to the take up of new technology. We have invested in small diameter pipe scanners to better service the power generation industry.

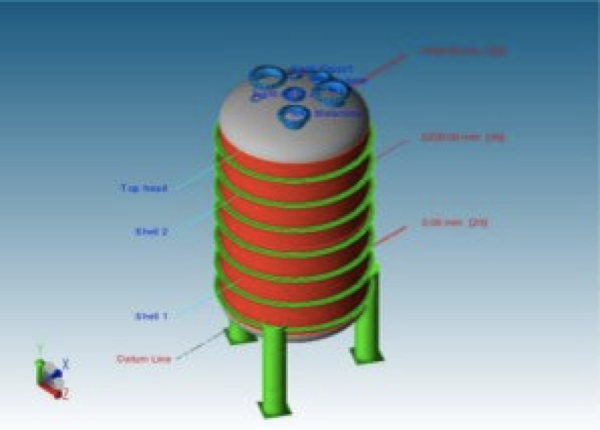

ARI have experienced design engineers with tertiary qualifications in mechanical and process equipment engineering. We have the capability to design, verify and determine fitness for service for pressure equipment utilising Australian and International standards.

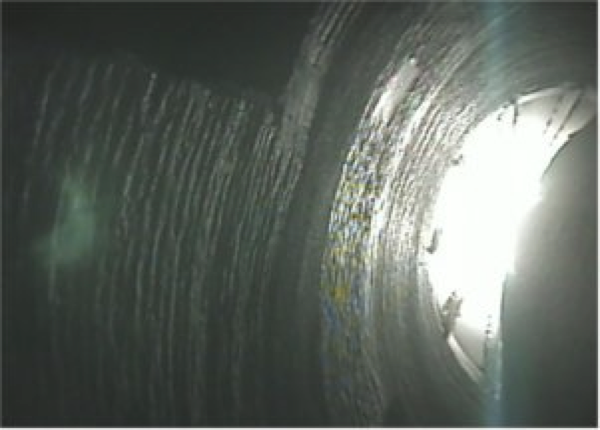

ARI have professional Olympus IMS videoscopes that enable us to perform confident remote visual inspections.

ARI have several multidisciplined ISO9712 Level 3 certified technicians. We can supply contract Level 3 technicians to facilities to assist with all aspects of ISO17025.